LEED Gold Certified Green Building

Ko Da Pharmaceutical upholds the principles of environmental sustainability and green innovation, earning the LEED Gold Certification. Our facility meets international green building standards across eight key categories including site selection, energy management, water efficiency, materials usage, and indoor environmental quality, achieving energy saving, carbon reduction, and sustainable development.

Smart Factory

Our new factory integrates a central monitoring system and smart energy management, utilizing automation and efficient production technologies to enhance product quality and consistency. The system leverages cloud computing, big data, and AI to provide transparent equipment status, process capability, and inventory visibility, serving as a command center for decision support, driving digital transformation and smart manufacturing to boost efficiency and reduce risks.

Energy Management

Ko Da continuously advances energy efficiency and carbon emission reduction, achieving ISO 50001 recertification and setting a 1.5% electricity saving target by 2025. We regularly audit energy-consuming equipment, upgrade to IE3 motors, variable frequency drives, energy-saving devices, and solar photovoltaic systems, optimizing chilled water units, air compressors, and boilers, while implementing 100% LED lighting and waste heat recovery.

New Manufacturing Facility Introduction

To elevate the traditional Chinese medicine (TCM) industry and align with international standards, Koda has established a modern manufacturing facility that complies with the Current Good Manufacturing Practices (cGMP) for Chinese medicine. Spanning from B1 to 5F, the facility covers a total floor area of 20,854.5 square meters (approximately 6,308 ping), and features a fully intelligent production line for scientific Chinese medicine—integrating automation and digital technology to enhance quality and efficiency across the board.

The exterior design is inspired by the concept of “Embracing diversity with a broad mind,” symbolizing our company’s open-mindedness and inclusive spirit in welcoming people, ideas, and innovations from all walks of life. It is also a visual commitment to continuous innovation for the future.

Guided by Koda’s core values of social responsibility and sustainable development, the new facility is built in accordance with the LEED Gold Certification (Leadership in Energy and Environmental Design). With features such as a wastewater treatment system, solar panels, and steam heat recovery from boilers, the facility embodies Koda’s commitment to environmental protection and energy efficiency—from source to end use.

LEED Green Building Highlights

Leadership in Energy and Environmental Design (LEED)

Through an integrated design approach, the facility maximizes building performance and sustainability:

Location & Transportation

Bicycle parking and shower facilities. Carpool parking spaces. EV charging stations

Materials & Resources

Construction waste recycling. Use of eco-friendly building materials. Waste segregation and recycling systems

Water Efficiency

Reclaimed water reuse. Water-saving fixtures. Smart irrigation systems with usage monitoring

Energy & Atmosphere

Energy modeling for design decision-making. Building energy management systems. Smart lighting. Variable-frequency air conditioning systems. Functional performance verification

Sustainable Site Development

Green landscaping to restore ecological habitats. Stormwater management Urban heat island mitigation. Light pollution reduction

Indoor Environmental Quality

Fresh outdoor air intake

M2.5 indoor air quality control. Low-emission building materials and pollutant control. Low glare lighting design

Equipment Upgrade & Smart Technology Integration

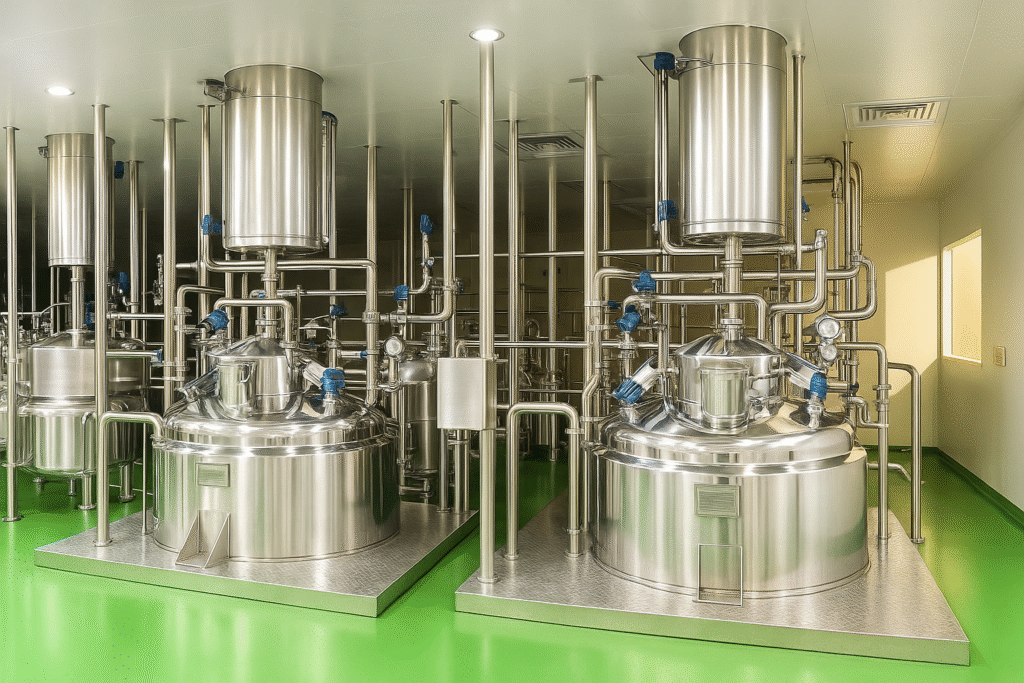

The new facility introduces state-of-the-art equipment, including extraction, decoction, and concentration systems, automated storage, robotic arms, wastewater treatment, and heat recovery systems. Technology is now embedded in every stage of our manufacturing process.

Koda has also strengthened our safety and quality monitoring systems to ensure that every product meets the highest standards. Koda’s aim is to modernize and rejuvenate Chinese medicine, making it a safe and trusted choice for today’s health-conscious consumers. Looking ahead, Koda will continue integrating AI and smart technologies to pioneer the next generation of TCM manufacturing.

The completion of Koda’s new facility marks not only a milestone in company’s development but also a shared step toward a more sustainable future for all.

Scientific Chinese Medicine Production Process

Selection and Storage

Chinese herbs must be selected according to the standards of the Pharmacopoeia, stored under appropriate temperature and conditions to prevent contamination, deterioration, and cross-mixing.

Cleaning

Removal of non-medicinal parts, weeds, and defective herbs, using a 360° high-pressure water circulation system to eliminate impurities.

Herbal Slicing & Preparation

Herbs are selected, sliced, and dried under controlled temperature and humidity to preserve quality and active ingredients.

Processing (Pao Zhi)

Based on TCM principles, herbs are further processed to reduce toxicity, modify properties, and enhance therapeutic effects.

Weighing

Accurate weighing is essential to ensure consistent quality in production.

Extraction

Active components are extracted using solvents, influenced by particle size, extraction time, temperature, and equipment conditions.

Filtration & Separation

Herbal residues are separated from the extract to ensure purity.

Concentration

Using low-temperature vacuum concentration, the extract is concentrated into herbal paste.

Granulation

Herbal paste combined with excipients is granulated into particles for easy processing and usage.

Granule Refinement

Granules are screened to achieve uniform size before packaging.

Finished Product Packaging

Packaging must be clean and well-presented, with a secondary barcode for logistics and traceability.

Storage & Distribution

Products are stored and distributed under controlled conditions with first-in-first-out, issue management, and product recall mechanisms.