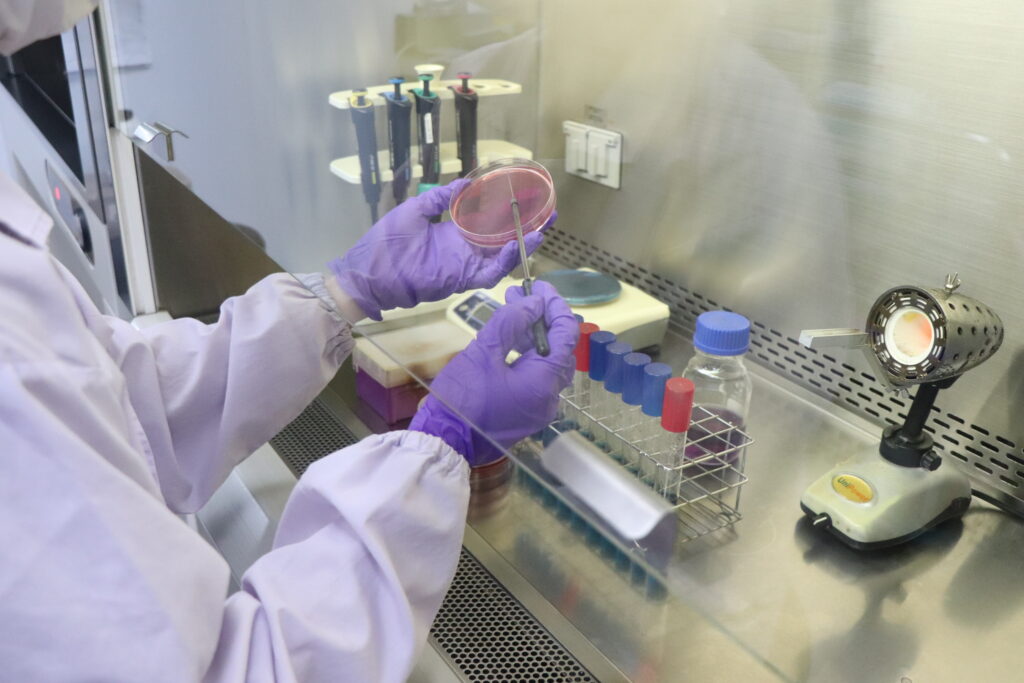

Quality Control

Ko Da Pharmaceutical upholds the philosophy of “Total Participation, Total Quality, and Customer Satisfaction,” and has built a comprehensive quality control system. Every batch—from raw material intake, in-process monitoring, final product testing, to pre-shipment inspection—strictly follows Standard Operating Procedures (SOP). We implement international standards such as ICH, PIC/S GMP, and ISO 17025, supported by advanced equipment including HPLC, GC, UV spectrophotometers, and ICP-MS, to ensure product safety, efficacy, and consistency.

Manufacturing Process

Ko Da Pharmaceutical adopts automated and smart manufacturing systems. From raw material pretreatment, extraction, concentration, drying, and granulation to final packaging, all processes are seamlessly integrated in a continuous flow. Our operations comply with PIC/S GMP standards, and high-grade cleanrooms (Class 100,000) are utilized to maintain strict environmental control. With the MES (Manufacturing Execution System) in place, we achieve real-time monitoring, batch traceability, and transparent quality management to enhance both production quality and efficiency.

Fully automated extraction and concentration systems to ensure stable active ingredients.

Low-temperature vacuum drying preserves herbal potency.

Cleanroom environments to prevent cross-contamination.

MES system monitors every production stage and parameter in real time.

Herb Traceability

Ko Da upholds the principle of “traceable origin, controllable quality” through a rigorous supply chain system. From the source, all herbal raw materials are carefully selected, tested for authenticity, and screened for pesticide residues. Upon arrival, materials undergo physicochemical testing and triple herbal identification (macroscopic, microscopic, and chemical analysis) to confirm authenticity and quality. Through ERP and barcode tracking systems, we maintain complete traceability from warehouse to production, ensuring safe and trustworthy herbal medicine for consumers.

Transparent sourcing with origin documentation.

Rapid screening for pesticide residues, heavy metals, and sulfur dioxide.

Triple authentication of herbal ingredients.

ERP and barcode systems record each batch’s movement and use.

R&D and Innovation

Our R&D efforts focus on the modernization of Chinese medicine, working with healthcare institutions and academic partners to enhance clinical relevance. Our team actively develops new formulas, refines manufacturing techniques, and explores advanced dosage forms to improve practical efficacy and global competitiveness.

KODA’s Scientific Chinese Medicine Quality Testing

General Testing

The quality of Chinese herbal materials is tested according to the Taiwan Pharmacopoeia standards to evaluate the quality of the materials:

- Loss on Drying

Checks the moisture content; excessive moisture can cause spoilage and mold. - Ash & Acid-Insoluble Ash

Determines non-volatile inorganic salts content; reflects material cleanliness.

Authenticity Identification

Herbal materials come from plants, animals, and minerals with similar appearances; authenticity must be verified.

Identification Methods:

- Macroscopic Observation

Observes color, odor, size, and texture of the material. - Microscopy

Observes tissue slices under a microscope. - Physicochemical Tests

Includes color reactions, gas-producing reactions, etc. - Impurity Inspection

Checks non-medicinal parts and other impurities. - (TLC) / TLC Identification

Qualitative test to verify marker compounds. - HPLC Fingerprint

Establishes chemical fingerprints and quantifies marker compounds.

Sulfur Dioxide Residue Test

Some herbs are fumigated with sulfur for preservation; residual SO₂ must be below 500 ppm.

Essential Oil Content Testing

Essential oils are key bioactive components; analyzed using GC or GC-MS/MS according to pharmacopoeia standards.

TLC Identification

Qualitative analysis supports authenticity verification and checks if raw materials and products contain expected compounds.

Aflatoxin Testing

Certain seeds and herbs may produce aflatoxins under improper conditions; total limit <15 ppb.

Aristolochic Acid Testing

Herbs containing aristolochic acids (e.g., Aristolochia, Stephania) are banned; tested by HPLC/UV or LC-MS/MS.

Heavy Metal Testing

Tests for lead, arsenic, cadmium, mercury; regulatory limits: Pb<10ppm, As<3ppm, Cd<0.5ppm, Hg<0.5ppm.

Pesticide Residue Testing

Cultivated herbs may contain pesticide residues; multi-residue analysis by GC-MS/MS and LC-MS/MS.

Marker Compound Testing

- Raw Material

Quantitative analysis of markers ensures stable raw material quality. - Finished Product

Quantitative analysis of multiple markers in finished products ensures uniformity and stability.

Microbial Testing

Herbs and products may contain microbes; tests for total aerobic bacteria, E. coli, and Salmonella ensure hygiene and safety.